Graphene is well on its way to becoming the next industrial revolution. Dubbed as the wonder material, it is already being used in a lot of the industries and will be making further impacts on other industries as well, due to its potential and applicability with other materials. Ever since its discovery in 2010, it has become the cheaper, lighter and stronger alternative to most other used materials in almost all industries. In the future, it may have a bigger impact in cost efficient, environment friendly, green production.

Technology and industrial revolution is a constantly changing concept. It started off with the discovery of fire in the prehistoric era and gradually proceeded with the inventions and discoveries of the likes of wheels, gravity, the concept of zero, steam, electricity, plastic and others that shaped and reshaped civilization through history. In the modern world, information, technology; electric and electronic energy usage is dominating the industry. But in times as recent as 2010, the newest heat in technological and industrial revolution is graphene. A material that is so exciting and full of potential that scientists began speculating about building an elevator to the moon with it.

First discovered in 2004, graphene is basically the thinnest layer of graphite. Scientists Andre Geim and Constantin Novoselov isolated graphene by separating fragments from a graphite slab with sticky tape until they achieved single atom layer thick flakes. A very complex and intricate method indeed. The process may seem silly but it earned Geim and Novoselov a Nobel prize.

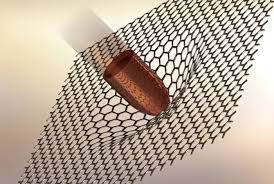

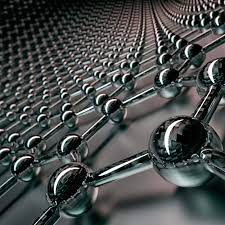

Graphene flakes, at just 0.33 nanometers, are virtually two-dimensional with no attainable z-axis. Such properties give graphene a remarkable crystalline structure. The atoms consist of hexagonal carbon rings, giving the entire flake a honeycomb or chicken wire like structure. This rigid yet simple carbon structure added with its incredibly light weight of merely 0.77 mg per square meter makes graphite the only existing two-dimensional molecule in existence. It is also very flexible and can easily stretch upto 25% of its measurements.

The same carbon structure also makes it the most rigid material in existence as of now. It is two hundred times stronger than steel. The smooth, flat hexagonal structure further means it has almost no resistance for electrons to pass through it, making it an excellent conductor of both electricity and heat. In short, graphene is the lightest, strongest and most conductive material in existence right now. Properties which open many doors and opportunities in innovation and upgrade. Opportunity which many businesses and scientists have been implementing in bettering everyday materials in many different industries. It came to be known as the wonder material because of how effective and versatile it becomes when combined with other materials. Graphene already has various applications and is still coming up on many opportunities for even more applicable industries, creating new possibilities in the market.

Initially graphene had made a commendable impact on the sports industry, for example, the multimillion dollar sports equipment company “Head” has incorporated graphene into their new tennis racket lines. This combination produced a new range of strong and flexible tennis rackets which were well received by consumers. Following suit, Grays have produced graphene infused hockey sticks and graphene enhanced bicycle tyres have also been launched by well known companies like Goodyear and Vittoria. A promising aspect in the sports industry regarding graphene is within the bicycle industry as they are researching graphene bike frames. A showcase has already taken place in Korea regarding extremely lightweight bike frames. So a new line of very durable and lightweight bicycles may be closer than we think. Graphene’s durability and thermal regulation also gave way to its incorporation in athletic garments. Athletic shoes have been designed by using graphene enhanced rubber which is 50% more flexible and stronger than regular rubber. Campaigns for graphene enhanced clothes like everyday jeans and jackets have also been initiated in crowdfunding platforms, which hints at a possible graphene enhanced garments industry.

Graphene already has various applications and is still coming up on many opportunities for even more applicable industries, creating new possibilities in the market.

Graphene can be used to enhance the strength of other materials. Many research demonstrations showcased how a small amount of graphene can increase the strength of metal, plastic, glass and other materials while reducing the weight. Many graphene enhanced composite materials can be used in mobile devices, building materials, ships or aerospace applications. Graphene induced protective coatings have been used in ship hulls.

Being the most heat conductive material, graphene can be utilized in electronic devices to avoid overheating issues and heat dispersion solutions. It can be used in LED lights to make them last longer or in products like heat dissipation films. It can also be used in thermal foils for smartphones, as can be seen in the Huawei X10 phones, which use graphene in their cooling systems. Graphene’s higher surface area to volume ratio makes it very effective in batteries, supercapacitors and fuel cells to store more energy and recharge much quicker. Graphene has impressive electronic properties and its large surface area makes it very sensitive to signals. That is why graphene is very effective in sensors. It showed promise in enhancing imagers and chemical sensors. Scientists have even found that it can detect quantum scale changes in conduction. Some companies are working on a graphene based hall-effect sensor that can measure magnetic fields.

Many of these graphene based sensors were used in medical fields to fight against COVID-19. Researchers created a graphene enhanced sensor that could detect the spike in protein in COVID positive DNA samples. Some companies also designed graphene enhanced face masks that ensured further protection against the virus. Moreover, graphene can also be utilized in dentistry. Multiple research shows that Graphene Oxide or GO in regenerative dentistry, bone tissue engineering, and other applications in dental biometrics and oral cancer. The functional group on graphene surface has the ability to DNA, protein and polymers which can be barrier breaking qualities in the fields of biomedicine. It has proven especially effective in restoring missing or damaged teeth due to its use in tissue engineering and tissue inductive treatments. Also, when GO scaffolds have been used in treating broken bones it has shown bone formation rates five times faster than the usual collagen scaffolds.

In the automobile industry graphene has shown promising impact on multiple angles. As we already know, graphene enhanced tyres and ship coatings are already in use. Additionally, anti corrosion coats and paints have also been developed using graphene. Furthermore, longer lasting car tyres are also out in the market along with a graphene based lubricant known as “Graphenoil” that boost engine performance much better. Graphene can be used in improving vehicles and roads as well. As 0f 2020, Ford has incorporated car parts improved by graphene into all their vehicles for better strength and weight. Furthermore, adding graphene to road construction is also being trialed in several places around europe. For instance, The Graphene Engineering Innovation Center is researching ways to incorporate graphene into roads and highway construction within the UK.

Graphene has even made its way into the quantum computing industry as researchers at nagoya University, Japan are trying to incorporate Graphene in quantum computing, especially in optoelectronic responses. The research team is trying to update how computer architectures perceive and analyze images compared to how fast and effectively the human brain perceives images. The research team expressed how this study shows a better understanding on how graphene based artificial optoelectronic synaptic behaviors (in easy words, computers that pretend to be eyes) will lead to an optically controllable, humanlike computer that is far better at processing information than the current generation computers.

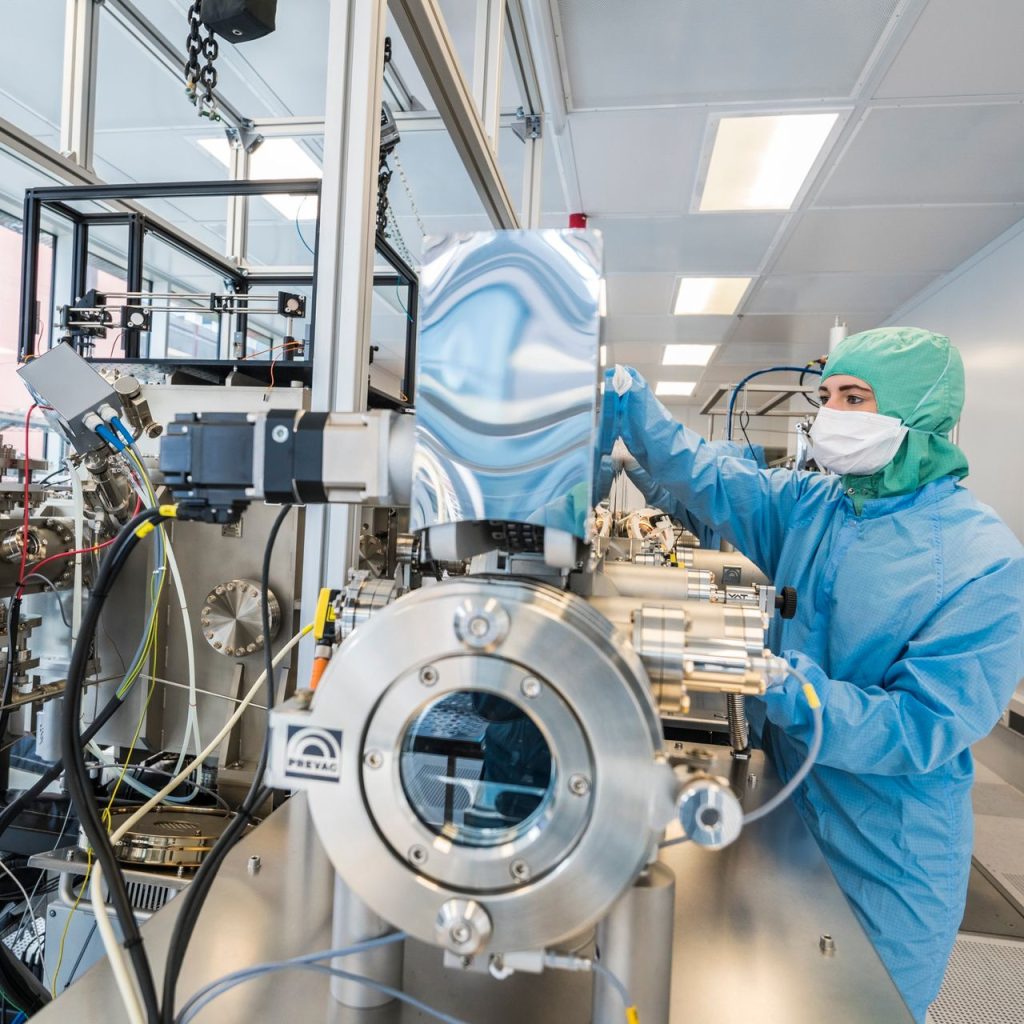

As we can see, graphene is well on it’s way to make a big presence in the bigger industrial scene and it may be here to stay. But like any other revolutionary material it can’t just be better than the existing production materials it also has to be accessible, achievable and, in simple words, present. As of now, there is still more work to be done, before graphene becomes a default option for businesses. Several production issues such as, the production procedure of chemical vapor deposition (CVD), which is the best method for producing single layered graphene limits the production scale. This issue limits the number of people who can manufacture graphene. Furthermore, consistency in equality differs from one batch of produced graphene to another. Much work needs to be done in assuring batch to batch quality maintenance and continuing large scale production in single layer graphene. Companies and end users are being informed on how to apply graphene in different ways according to their production needs and costs. As soon as these issues are tackled. A wide scale industrial takeover by graphene from unseen, high stake usages to everyday, household items can be a norm in the future industrial world.